How to build a cement plant YouTube

Nov 27, 2012· Watch the film telling about the construction of the Holcim plant in St. Genevieve. Showing the process'' from engineering to project planning to manufacturing and the construction of the plant ...

WhatsApp)

WhatsApp)

Nov 27, 2012· Watch the film telling about the construction of the Holcim plant in St. Genevieve. Showing the process'' from engineering to project planning to manufacturing and the construction of the plant ...

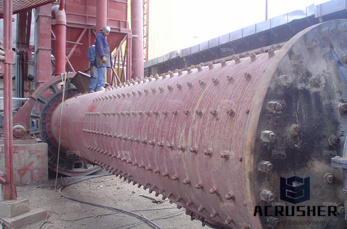

A tube mill is a revolving cylinder of up to five diameters in length used for fine pulverization of ore, rock, and other such materials; the material, mixed with water, is fed into the chamber from one end, and passes out the other end as a slurry. Both types of mill include liners that protect the cylindrical structure of the mill from wear.

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or cause spalling – thus shortening working life, increasing downtime and increasing costs.

3 A m x 20 m mill shell on its way from France to Malaysia. With an extensive range of grinding systems, consisting of x tube mills, x rod mills, x autogenous and semiautogenous mills, x AEROFALL mills, x roller mills and x POLYCOM® highpressure grinding rolls including x separators, x cement coolers, x dryers and x expert systems for automatic process control, ...

Cement Production Line Cement Grinding Plant Industrial Kiln and Furnace Grinding Equipment|ball mill|tube mill Crushing Equipment Environmental Protection Equipment Cooling Equipment Drying Equipment Compound Fertilizer Equipment Conveying Lifting Packing Equipment Active lime production line Roller Press ...

Dry Process Raw Mill In Small Scale Cement Plant, Find Complete Details about Dry Process Raw Mill In Small Scale Cement Plant,Cement Ball Mill Design,Industrial Grinding Mill,Cement Tube Mill Design from Cement Making Machinery Supplier or ManufacturerJiangsu Haijian Stock Co., Ltd.

complete set of cement machinery Active lime production line Cement grinding plant industry kiln/cement rotary kiln/lime rotary kiln Tube mill/Ball mill/Cement mill/Coal mill/Slag mill/Raw mill/Mining mill vertical mill/roller press/grinding equipment Product of Crusher Series Dust collector/environment equipment Compound Fertilizer Equipment .

• cement industry: Nghi Son, Vietnam, 1998,Guangzhou, China, 2005. Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. The development was first realised in 1970 for grinding mills in the cement industry. This number of rollers also enables operation with only one pair

Apr 15, 2018· Plant में सीमेंट किस तरह से बनती है? How to make make Cemen in Plant? ... How Ball Mills Work (Engineering and Mining ... How to build a cement plant ...

Tube mill. Polysius supplies tube mill systems for drying and grinding a very broad range of different materials. Selection of the appropriate system for the particular application depends on different parameters, such as feed size, grindability and moisture content and drying properties of the raw material.

BECKUM Portlandzementwerk Wotan H. Schneider from Üxheimütte in the Volcanic Eifel has acquired a Pipe Conveyor manufactured by BEUMER Group to transport clinker to its cement mill. The 200metrelong conveying system is customised to fit perfectly into the local environment.

Our company is one of the most powerful national manufacturers to produce tube mill. After exploration and summary in the design, manufacture and use for a long time, we have obtained different specifications, different functional requirements and variety series products.

Jan 16, 2018· This video shows some upgrades I made to the Valley Cement kit from Walthers. I am not using this as a cement plant, I just liked the look and will reposition the buildings. One of the buildings ...

Welcome to AIA Engineering/Vega Industries. Specialist in Cement, Mining, Power and Aggregate Businesses

The mill with the compact drive version features an INTEGRAL DRIVE, whose planetary gear is mounted to the mill flange. KHD Humboldt Wedag mills are the result of the most advanced calculation and simulation methods, backed by years of experience. Worldwide we have designed and built more than 1,000 tube mills.

Nov 10, 2017· Cement mill se Judi jankari aur adik jankari pane के लिए हमारा चैनल लाइक करें और सब्सक्राइब ...

The GRMK vertical cement mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions. It can save 30% of power per ton compared with traditional ball mill. ... It is widely used in clinker grinding production of cement plant and slag grinding plant.

Operation of Tube Mills in Cement Plant. Grinding systems with tube mills have been operated throughout the world for many decades. Many practical ways to operate these mills in an easy way have been developed and many improvements introduced, including the application of new technologies.

Various forms of ballandtube mills, initially promoted by FLS and Polysius, were gradually displaced by "combination" mills, as also occurred in raw and finishgrinding. The Unidan mill feeding an indirect system continued as the preferred setup on most FLS plants into the 1960s. Highspeed mills

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Description of Tube Grinding Mill: Our tube grinding mill is typically designed for grinding different kinds of ores and many other grindable materials, and it can be widely used in building materials, metallurgy, chemical industry, electricity industry, and many other industrial or mining fields.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

4 Due to the interaction of raw materials and kiln gases, rotary kiln systems have inherent SO2 removal efficiencies ranging between 4099% of the sulfur input to the system. The literature suggests that 5070% of the remaining SO2 will be removed from exhaust gases when passed through an inline raw mill .

WhatsApp)

WhatsApp)