COMMON HAZARDS AND CONTROL MEASURES IN CEMENT .

Jun 30, 2015· COMMON HAZARDS AND CONTROL MEASURES IN CEMENT PLANT Published on June 30, 2015 June 30, 2015 • 30 Likes • 4 Comments

WhatsApp)

WhatsApp)

Jun 30, 2015· COMMON HAZARDS AND CONTROL MEASURES IN CEMENT PLANT Published on June 30, 2015 June 30, 2015 • 30 Likes • 4 Comments

The height of stacks should not exceed the height of the walls, and a space of at least 1 metre should be allowed between the tops of stacks and roof frames. (iv) Separation of lots. Maximum use of the warehouse is gained by storing products in one stack.

stack height impacts on pollutants dispersion (Heckel et al., 2011). In addition it used to predict NO 2 dispersion from a cement plant have been investigated by using AREMOD software

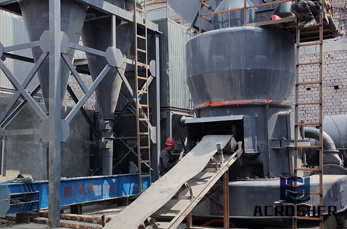

The dimensions H and A in turn describe the height of mills with classifier, the footprint diameters and the overall space required, taking a service area (for replacing grinding parts) into consideration. Mill sizes are identified according to the outer effective diameter of the grinding track in decimetres [dm].

Height Unit . 400° K m 90 m ... for Kiln/Raw mill stack in order to provide instantaneous . ... The effect on soil around the cement factory was also studied by collecting samples in the four ...

Oct 21, 2019· Using an appropriate stacking method is one of the best ways to keep a stack from collapsing. Try one of these options: • Block Stacking – Stack square items in a cube, making sure to secure them with some kind of strapping like wire or plastic shrink wrap. • Brick Stacking – To ensure even more security, turn each level of a stack 90 degrees. . This helps hold the items in place ...

No cement bags should be stacked in contact with an external wall. A clear space of at least 60 cm should be left between the exterior wall and the stacks. Cement bags should be placed closely together in the stack to reduce circulation of air as much as possible.

A stack of bricks must not be more than 7 feet high. If the bricks are loose, a stack of 4 feet or more must have 2 inches of taper for every additional 1 foot of height. A stack of masonry blocks that reaches 6 feet must taper onehalf of a brick per layer of blocks.

Cement bags shall be stacked on wooden planks maintaining a minimum clearance of 200 mm from the floor. A minimum clear space of 450 mm shall be provided between the stacks and any exterior wall. Maximum height of the stack shall be 15 bags and the width not more than four bags or .

Finally, the model showed that the stack heights and exit velocity are controlling factors in pollutant dispersion, where the relation between the stack height and the exit velocity against the maximum pollutant concentrations is inversely proportional. Moreover, this model was applied to a current cement plant located 30 Km south of Cairo.

Jun 25, 2013· Cement mill certificates, also called mill test reports, contain a lot of information that can prove useful for tracking changes in your concrete and controlling variability in your mix. Usually this certificate must be included in submittal documents to show that the cement conforms to the requirements of applicable specifications, such as ...

Sh Cement Ltd. has been the leading cement brand of Bangladesh for over 15 years, a concern of Abul Khair Group, largest group of companies in our country.

Study the effect of increasing stack height In order to study the effects of stack height on contaminant dispersion and concentration, a total of four model runs (increased stack height from 80m to140m with interval 20m) were completed. The emission stack data for the four model runs as shown in Table 1, Table 2and Table 3[9].

SIBLINE is one of the major clinker and cement producers in the Republic of Lebanon. Sibline currently produces 3,400 tons of clinker per day. Thus, resulting with an annual production of cement exceeding Million tons. In addition, Liban sal, a subsidiary company of SIBLINE, produces readymix concrete at an annual capacity of 200,000m3.

cement mill. Dust extraction and pollution control system consisting of highly efficient bag filters and ID fan have been provide for cement mills, clinker silo, fly ash storage silo and cement silo. Stack height of Cement mill of Bihar Cement Plant is meter and Cement mill of New Bihar Cement Plant is .

A fluegas stack, also known as a smoke stack, chimney stack or simply as a stack, is a type of chimney, a vertical pipe, channel or similar structure through which combustion product gases called flue gases are exhausted to the outside air. Flue gases are produced when coal, oil, natural gas, wood or any other fuel is combusted in an industrial furnace, a power plant''s steamgenerating boiler ...

Particulate matter emission from a stack attached to the kiln and raw mill in a cement plant was studied. Elemental (As, Cd, Co, Cr, Cu, Fe, Mn, Ni, Pb and Zn) and ionic (Ca 2+, NO 3 −, SO 4 2−) composition and particle size distribution of stack particulates, principal raw materials and products were feed rates of raw meal were found to be 144 and 18 t h − 1 at cyclone ...

stack height diameter. i want to calculate the height diameter of the stack after esp of preheater raw mill ? how to calculate? similarly how can i calculate the stack height of grate cooler vent air? what are the requirements how it is done? please explain in an excel sheet. please reply . sidhant . reply. know the answer to this question?

stack height diameter. i want to calculate the height diameter of the stack after esp of preheater raw mill ? how to calculate? similarly how can i calculate the stack height of grate cooler vent air? what are the requirements how it is done? please explain in an excel sheet. please reply . sidhant . reply. know the answer to this question?

J1 Stack Gas Emission Standards from Environmental Quality (Clean Air) Regulations 1978. J2 Recommended Malaysian Air Quality Guidelines (Ambient Standards) 53 K1 Extracted From Environmental Quality (Sewage) Regulations 2009 (PU (A) 432) 54 .

The aggregate from the weigh hopper is dropped into the mixer (pug mill) and drymixed for 6 to 10 seconds. The liquid asphalt is then dropped into the pug mill where it is mixed for an additional period of time. At older plants, RAP typically is conveyed directly to the pug mill from storage hoppers and combined with the hot aggregate.

The stack height and stack inside diameter are used for PM 10 dispersion modeling . Table 1 . Parameters related to the three stacks (Electro filter 1, 2 and Kiln) of cement plant.

Smokestacks are chimneys that let smoke and combustion gases escape from buildings such as homes and factories. Factory smokestacks vary in height due to local wind and atmospheric conditions. Electrostatic precipitators use electrodes to capture particulates in smokestack emissions.

Dec 11, 2018· Q: Cement mill seperator Hi sir We have a closed circuit cement mill and documentary of the seperator is SKSZ3500/290/4*3200 . The seperator included of dynamic and static separator The static seperator have 100 blades (50blades in up and50blade in down). The rotation of the seperator is between 43 to 170

WhatsApp)

WhatsApp)