(PDF) DESIGN AND FABRICATION OF MINI BALL MILL .

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the ...

WhatsApp)

WhatsApp)

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the ...

Dec 10, 2009· Crash Course in Milling Tutorials Made for Machinists by Machinists Chapter 8: Choosing Using Endmills Our "Crash Course in Milling" training series for conventional and CNC milling machines ...

MILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal. These machines are also classified as kneetype, cutter containing a number of cutting edges. The milling ramtype, manufacturing or bed type ...

If you''re doing significant manufacturing, these are not for you. If you need a basic endmill to do some basic hobbyist milling, these are a great value for the price, but know there are much better tools out there, but also at a much higher price. Personally, I use these for milling 6061 as a hobby and they always perform good enough for my needs.

Jan 15, 2016· An easy way to set up a lathe for milling. How To Make A Low Cost Indexing Chuck Assembly For The Bench Or Pillar Drill Duration: 15:58. Steve Jordan 727,482 views

Apr 03, 2013· If you think you have a mill that is very accurate, ways all scraped in, no runout in your spindle, then maybe it makes sense to go with the higher res scales. As one old tinkerer to another, one more piece of advice. Don''t let the perfect be the enemy of good. I have low res scales on my mini mill and working with a DRO is great.

This is a particularly important value when using round insert cutters, ball nose end mills, and all cutters with larger corner radii, as well as cutters with an entering angle smaller than 90 degrees. Spindle speed, n. The number of revolutions the milling tool makes per minute on the spindle.

Ball Transfer Systems, LLC. is a leading manufacturer of heavy duty and light application industrial ball transfer units. Our omnidirectional ball transfer units are made of the highest quality materials for durability and efficient material handling.

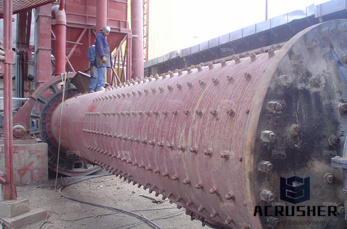

Jul 20, 2019· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50% of the mill volume and its size depends on the feed and mill size.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

CNC Conversion Kits for the Seig X3, SX3, and Grizzly G0619 and G0463. Plus Shop Fox M1111 Table Top Mills. We have a full CNC unit in stock! Also available with premium ball screws

Drill, mill and cut slots, grooves and small parts with this powerful mini mill. A durable cast iron body and base help reduce vibration and deliver superior results. Two speed ranges, 0 to 1100 RPM and 0 to 2500 RPM, for working with a variety of materials and degrees of thickness.

Wiki researchers have been writing reviews of the latest mini mills since 2015. Currently, the best milling machine is the Precision Matthews PM727M. ... It is both a milling machine and a lathe in one handy unit that, surprisingly, doesn''t cost an arm and a leg. ... Some common tool heads include ball end mills, rounding mills, fluted mills ...

RETSCH is the world''s leading manufacturer of laboratory mills jaw crushers, sieve shakers sieves as well as sample preparation equipment.

item 2 10 PCS (LM20UU) 20mm Linear Ball Bearing Bush Bushing CNC Unit For Mini Milling 10 PCS (LM20UU) 20mm Linear Ball Bearing Bush Bushing CNC Unit For Mini Milling. Free shipping. No ratings or reviews yet. Be the first to write a review. Best Selling in Other Bearing Bushing Parts.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

When it comes to small and midsized mills, the frame and stand form one unit which leads to a high level of dynamic resilience (monoblock design). Largescale milling machines are generally designed in a modular fashion, but for any size of mill, the milling head is the key component. It can machine the workpiece on three sides simultaneously.

Retsch revolutionalizes grinding with an entirely new type of mill: the High Energy Ball Mill Emax. 1923 The company''s first own piece of laboratory equipment is developed, a mortar mill, which becomes known as the Retsch Mill and is synonymous with the concept of easier and better laboratory work. 1959

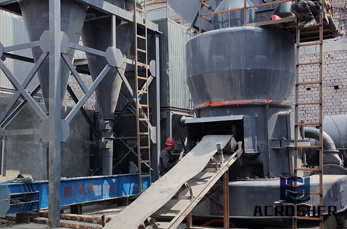

Laxmi Engineers Cement plant manufacturer, cement machinery india, cement plant supplier, cement machinery manufacturer, cement plant and machinery, manufacturers of mini cement plant, cement machinery suppliers, mini cement plant machinery, cement plant and machinery, mini cement plants, cement machinery exporters, mini cement plant suppliers, cement plant india, wholesale cement .

Crushers, Pulverizers, Grinders Knife Mill Blender Pulverisette 11 Knife Mill Blender Pulverisette 11 ... The Mini Ball Mill Pulverisette 23 is used for fine grinding of small quantities of dry samples or solids in suspensions, as well as mixing and homogenisation of emulsions. ... Aggregate Screening Units; Sonic Sifter Separator 3 ...

Nov 24, 2010· Incorporation of liquid nitrogen (cryomilling) is a common technique used for micronization of materials by a number of investigators (23,25–27). Hence, comparisons were made between cryomicroball milling and airjet milling to achieve optimum conditions for micronization of .

Technical Description. The Hanningfield UniMill USeries (M05U, M10U, M20U, M30U) utilises the current industry standard underdriven conical mill design, featuring an IP6X gearboxdriven impeller, rotating inside a screen (60º inclusive screen angle).This principle achieves comminution by compression and shearing of the particles between the impeller and surface of the screen.

PDF DESIGN AND FABRICATION OF MINI BALL MILL. May 30 2016 · This project is to design and fabricate a mini ball mill that can grind the solid state of raw materials into fine powder Ball mill is a cylindrical device that used to grind and blend raw

milling machine has a worktable that can swivel on the saddle with respect to the axis of the milling machine spindle, permitting workpieces to be adjusted in relation to the milling cutter. 2 The universal horizontal milling machine also differs from the plain horizontal milling .

WhatsApp)

WhatsApp)