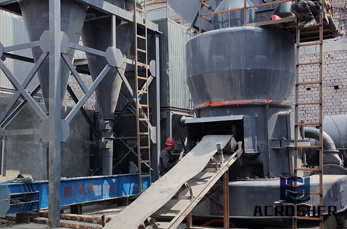

milling process of coal

Coal Gangue Milling Process sbmkitchenware Gangue processing production line,Gangue crushing plan mill . Coal gangue is a kind of solid waste in the process of coal mining and coal washing, It .

WhatsApp)

WhatsApp)

Coal Gangue Milling Process sbmkitchenware Gangue processing production line,Gangue crushing plan mill . Coal gangue is a kind of solid waste in the process of coal mining and coal washing, It .

Coal processing has two forms, here descripe flow chart of coal processing plant: Industrial process is the coal after the coal crusher, with the belt conveyor to quantitative feeder, to pressure the ball machine feeding by quantitative feeder uniform, sometimes need to improve the coal briquette strength, therefore, quantitative feeder and intermediate pressure ball machine can also add ...

Coal Milling Process solarthinktank. coal mill process plan . coal crushing and milling process flow taiwan mine . milling process of coal swiming. process coal milling 32861 thelinkcoin. rock crusher duty rock crusher, mill machine,jaw crusher,ball mill,r Grinding is the required powdering or pulverizing process when final size of below 2 mm is needed coal milling process .

Coal processing has two forms, here descripe flow chart of coal processing plant: Industrial process is the coal after the coal crusher, with the belt conveyor to quantitative feeder, to pressure the ball machine feeding by quantitative feeder uniform, sometimes need to improve the coal .

In coal milling for power stations, a ''closedloop'' process is used in which the rejects from the classifier are returned to the mill for regrinding. In VSMs, the recirculation loop is within the mill, but some mill types would have an external loop.

To help ensure your coal milling assets are performing per your plant''s key performance indicators, we offer a full line of parts, service, and solutions: ... GE''s PVPRO mill upgrade system uses a patented process to provide better control of coal fineness and reduce .

Jul 01, 2020· Pyongsan Coal Mine. The first step in the Pyongsan process flow starts at the colocated coal mine to the north of the mill. From this mine, coal is moved to a primary coal processing plant (CPP). At this location, the mined coal is crushed to a size that allows it to be transported by piping to a secondary CPP inside the main milling complex.

coal milling and drying process. coal drying improves performance and reduces emissions. coal drying improves performance and reduces emissions1 charles bullinger and mark ness great river energy process layout, coal drying equipment and impact of fuel moisture on plant performance and emissions are discussed. with less fuel moisture, more complete drying of coal can be achieved in the mill

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Development of Mill. high in water content, and the humidity in the mill increases as a result of the drying process The mill outlet condition (low O2 and high humidity) is a more severe condition for combustion than that of a conventional system with bituminous or subbituminous coal, and these issues raise...

Coal milling process educationcarein coal preparation is the first step in the whole process of coalfired power coal milling process by zhang et al in 2002 which is a multiinput more details get price coal milling machine is coal milli...

Coal Milling Projects (CMP) was formed in 1997 by Andrew Robinson, Dave Mckay, Kotie Steyn to provide specialist products and services in the field of coal milling and related technologies. CMP is the Southern African sales representative for Southwestern Corporation, an American based Company specialising in coal mill maintenance and ...

milling process of coal manufacturer in Shanghai, China. milling process of coal is manufactured from Shanghai Xuanshi,It is the main mineral processing solutions. Chat With Sales. coal mill working process jspfoundation. Coal mill is an important auxiliary equipment for coalpowder furnace, it has three . A coalition mill can be any device

Coal dust is a type of fine coal powder ground by coal grinding mill, size range ~, and most of powder''s size range 20~50μm. Pulverized coal processed by grinding machine could be fully burned, use ratio very high, and we have provided technical support for many power plant.

Over the last few decades, the airswept vertical roller mill has become the standard solution for coal grinding installations. Continuous improvement of the ATOX coal mill has resulted in today''s ...

Working process of coal pulverizer milling machine products list pulverizer a ball mill is a pulverizer that consists of a horizontal rotating the balls are simply consumed by the wear process and must the ball and tube mills are lowspeed machines that. Standard Operating Procedure For Coal Pulverizer.

Milling Process in Vertical Mill • The coal feeder discharge spout is connected to the inlet pipe located centrally in the mill and discharges onto the rotating table. Thus the crushed coal of <50 mm size lands at the center of the grinding table at the start of the milling.

Processing the Coal. After coal comes out of the ground, it typically goes on a conveyor belt to a preparation plant that is located at the mining site. The plant cleans and processes coal to remove dirt, rock, ash, sulfur, and other unwanted materials, increasing the heating value of the coal.

Metallurgical coal – or coking coal – is a vital ingredient in the steel making process. World crude steel production was billion tonnes in 2018. Manufacturing steel delivers the goods and services that our societies need – healthcare, telecommunications, .

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more .

To help ensure your coal milling assets are performing per your plant''s key performance indicators, we offer a full line of parts, service, and solutions: ... GE''s PVPRO mill upgrade system uses a patented process to provide better control of coal fineness .

SAP is the leading provider of software solutions for the Mill Products and Mining industries. We offer a broad innovative solution portfolio for the sectors mining, metals, building materials and products, cement and concrete products, pulp, paper and packaging, plastic manufacturing and textiles.

Pulverizer Wikipedia. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for combustion in the The balls are simply "consumed" by the wear process and must be restocked, whereas the liners must be periodically replaced.

milling process of coal is manufactured from Shanghai It is the main mineral processing solutions TON stone crushing machine projectmilling process of coal ShangHai TON (milling process of coal) are a professional production of stone crushing machine Sales and Widely used in Europe South America Africa East Asia and Asia region get price.

WhatsApp)

WhatsApp)