(PDF) METHODS OF SIZE REDUCTION AND FACTORS AFFECTING .

Optimum machine performance can be obtained at MC of %, RBTS of m s1 and SPD of mm. At these settings, predicted values of grinding capacity, grinding recovery, and APD are .

WhatsApp)

WhatsApp)

Optimum machine performance can be obtained at MC of %, RBTS of m s1 and SPD of mm. At these settings, predicted values of grinding capacity, grinding recovery, and APD are .

Machine tool, any stationary powerdriven machine that is used to shape or form parts made of metal or other shaping is accomplished in four general ways: (1) by cutting excess material in the form of chips from the part; (2) by shearing the material; (3) by squeezing metallic parts to the desired shape; and (4) by applying electricity, ultrasound, or corrosive chemicals to the ...

Therefore, these parts have to be flipped when deburring is taking place, which can be a dangerous proposition (see Figure 1). The Rise of Automated Deburring and Grinding. In the early 2000s machine tool technology emerged that can alleviate the dangers of manual deburring and grinding, reducing injury risk for employees.

They can be brought to the metal without much physical effort and can be used in areas with limited space. The machine is set within a few seconds and the bevel heads are replaced within 45 seconds. A perfect bevel is achieved faster; on average 4 feet (1 metre) of .

CNC Router Engraving Machine Rotational 4th Axis Rotary Table A Axis 3 jaw 80mm chuck+65mm Tailstock CNC dividing head+Nema23 Stepper Motor Milling Lathe Chuck Fourth Axis K1180mm Reducing Ratio 6:1 out of 5 stars 2

Besides, highquality grinding discs as well as flap discs work with rightangle grinders as a system. An old jalopy (that is, a lowquality grinder) with fancy tires (highquality grinding disc) may drive a little better, but it''s still not the smoothest ride. 2. Be safe. Using the .

creates a land area to reduce backlapping time. Cylindrical grind: For a cylindrical grind (spun ground), the reel is rotated as the grinding wheel is traversing. This is accomplished on a machine called a spin grinder. Spin grind creates a more accurate diameter control of the reel. A properly spunground reel should not need backlapping.

Using a diamond grinding wheel is recommended to prevent overheating or damaging the bedknife edge while grinding. Figure 4. Because the top grind angle on bedknives is critical for edge retention, and therefore aftercut appearance, Toro has develop special service tools for accurately measuring the top grind angle on all bedknives (Toro ...

Dec 31, 2015· Grinding 1 inch of concrete? This topic has 18 replies, 13 voices, and was last updated 4 years, 8 months ago by Doobie. Viewing 19 posts 1 through 19 (of 19 total) Author. Posts. December 30, 2015 at 7:25 pm #449102. MJconstruction. Pro. In one of the buildings i work in water is getting under the large garage door. The problem is that the ...

Concrete grinder machine . Lease sale of concrete grinder machine . pwm sales concrete grinders and polishers. the after sales service and operated in the counter rotating mode it is a high performance grinding and polishing machine . view concrete grinders for sale in australia machines4u. of course, the other common reason for using a concrete ...

grinding machines for reducing edge of 1; Reducing the surface roughness in grindingReducing the surface roughness in grinding, [1] To reduce the surface roughness, increase in the number of wheel contacts with a specific section of blank is recommended, by Best Bench Grinders (Aug 2019)Jul 14, 2019· This large bench grinder from ...

Grinding fluids reduce grinding temperatures in two different ways. The first is by directly cooling the process within the grinding contact area. In creepfeed grinding, direct cooling is a powerful agent for reducing grinding temperatures. The second is by maintaining the wheel cutting efficiency.

On offhand grinding machines, work rests shall be used to support the work. They shall be of rigid construction and designed to be adjustable to compensate for wheel wear. Work rests shall be kept adjusted closely to the wheel with a maximum opening of 1/8 inch ( cm) to prevent the work from being jammed between the wheel and the rest ...

Multifunction Smash Machine,Electric Mill Spice Herb Grinding Machine Tool, Coffee Bean Milling Smash Machine,Electric Cereals Grain Seasonings Spices Milling Machine Grinder for Daily Use. out of 5 stars 7. 20. 99. 5% coupon applied at checkout Save 5% with coupon.

May 13, 2019· Incorrect: Straight cutting off wheels such as Type 41 (formerly denoted as Type 1) used on a portable angle grinder with a Type 27 28 raised hub or depressed center grinding wheel guard. Explanation: Type 27 28 guards are open on the bottom to allow for side grinding with raised hub/depressed center wheels. When side grinding with the Type 27 or Type 28 wheel, the work piece .

Sectioning Mounting Grinding Polishing Spectroscopy Petrography: Sectioning Machines: Sample preparation starts with "Cutting" and good "Cutting" means a good start. Selecting the right cutoff wheel ensures freedom from burn and distortion and is the best way to save time and consumables.

A doubletooth cutter with flat face grinding and a cuttingedge diameter of mm. It is used when 90° angles have to be milled, in drillings and abutments. For machining nonprecious alloys on a cobaltchrome basis and titanium, this tool is available as a torus cutter with a small edge radius which protects the cutting edges (only ...

A professional golfer may sometimes have a wedge ground to alter its playing characteristics to fit a particular course. Grinding the club head may change the wedge''s bounce, or it may sharpen or soften the leading edge. While wedge grinding is typically a job for professionals, a casual golfer who''s handy with tools and has an older club laying around may wish to experiment with wedge ...

Jul 01, 1970· A grinding operation where the grinding machine is designed to be hand held and may be easily moved from one location to another. PRECISION GRINDING Grinding operations performed by machines used to finish work parts to specified dimensions and finish requirements.

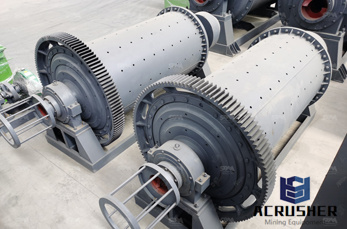

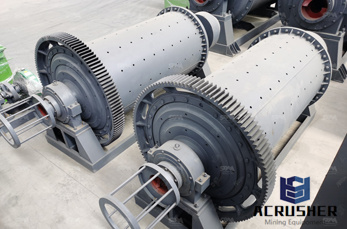

grinding machines for reducing edge of 1. feldspar grinding machines. Grinding Mill Raymond Mill Ball Mill Hammer Mill For . Feldspar grinding mill is special for feldspar pwoder making is also named feldspar grinding mill feldspar grinding machine and etc feldspar after processing can reach 3000 mesh mesh adjustable Shanghai Clirik Machinery Co Ltd is devoted the field of micro powder ...

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.. A wide variety of machines are used for grinding: Handcranked knifesharpening stones (grindstones)Handheld power tools such as angle grinders and die grinders; Various kinds of expensive industrial machine tools called grinding machines; Bench grinders

To prevent overheating, dip the chisel in a cup of water every five seconds or so. (If the water sizzles, reduce the grinding time to four seconds or less.) The end of the chisel doesn''t have to be perfectly square. Close is good enough. But it really needs to be straightkeep grinding if the edge is uneven.

Surface grinding machines for ceramics can be divided into (1) creepfeed grinding type and (2) reciprocating (speedstroke) grinding type. Reciprocating grinding works with relatively small depth of cut and high speeds (up to 40,000 mm/min) and requires particular specifications of the driving system such as high damping and acceleration.

Advantages of Endrunner mill and Edgerunner mill. 1. It produces fine particles. 2. Requires less attention during the milling operation. Disadvantages of Endrunner mill and Edgerunner mill. 1. It is not suitable for milling sticky materials. 2. Machine noise leading to noise pollution. References. Sud Sushant and Kamath Archana (2013).

WhatsApp)

WhatsApp)