igold mill plant design

Gold Mill Plant Design mayukhportfolio . gold ore bowl mill designShanghai Mining Heavy Machinery Co., Ltd. the design of crushing plant 300 ton/hour. 300 ton crusher plant design Crusher South Africa 300 ... Thola Intengo

WhatsApp)

WhatsApp)

Gold Mill Plant Design mayukhportfolio . gold ore bowl mill designShanghai Mining Heavy Machinery Co., Ltd. the design of crushing plant 300 ton/hour. 300 ton crusher plant design Crusher South Africa 300 ... Thola Intengo

The Gekko team has a particular interest in developing energy efficient, capital effective flowsheets, equipment, modular plant, and service solutions for gold, coal and polymetallic applications. Satisfaction is achieved on successful completion of smart, appropriate, technology and knowledge based solutions.

gold plant will be that of the leaching and carboninpulp circuit (CIP). The reagent and utilities operating costs associated with leaching, adsorption, elution and regeneration would typically make up some 15% of total ... The process design of gold leaching and carboninpulp circuits

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore ...

suitable mill feed size – which varies according to the crushing/grinding circuit – can achieve up ... years in metallurgical plant design, where he headed up a process design department as part of an international ... plant superintendent for several gold and base metal mining operations. Eric

Sampling of runofmine mill feed—A practical approach the successful application of this modified Gy''s model to design a means of establishing the minimum sample size and the various stages of comminution required for broken ores (particularly gold ores) within a specified precision range, for mineral processing plant feed. Sampling theory

May 13, 2015· Gold Ore Processing Plant, Crushing Quartz Hardrock Gold and Smelting Buttons to Sell for Cash Money ... Summer 2013 hard rock mill setup. Gold mining. .

MECS Sulfuric Acid Plant, Design Flow Rate 650 MTH to 1500 MTH. Inventory ID: 18CAR02. MECS Sulfuric Acid Plant, Design Flow Rate 650 MTH to 1500 MTH. ... 10,000 TPD CRUSHING/GRINDING CIRCUIT GOLD PLANT with 32'' x 12'' SAG Mill, '' x 28'' Ball Mills, 54" x 74" Gyratory, 7'' SH HD Cone, Rock Breaker and More. Manufacturer: ALLIS CHALMERS ...

Sepro Mobile Plants are designed to be easily relocatable as they are mounted on road transportable custom built trailer assemblies. These include the Sepro Mobile Mill Plant and Sepro Mobile Flotation Plant, both of which were installed by Banks Island Gold Ltd at the company''s Yellow Giant Gold Property on the coast of British Columbia.

Gold Recovery Plant For Sale: Centrifugal Concentrator for Minerals Recovery How To Efficiently Recover Fine Gold From Ore When you want to efficiently recover fine gold from gold bearing ore, you need a Centrifugal Concentrator (CC). ... Here are a few helpful hints from our resident expert on the Micron Mill Wave Table gold recovery device ...

Over the past 15 years, minetomill studies have focused attention on the impact blast fragmentation has on concentrator throughput. Blasting provides the first opportunity for comminution – or size reduction. It is also a cheaper and more efficient process, compared to both crushing and grinding.

yanacocha gold single stage sag mill design zenith. The CIC plant utilised by the Gold Mill process is part of the adjacent La ..... Mill power, bearing pressure and power draw were all significantly lower during. Read More

Canadian Malartic is one of the world''s largest pure gold producers. The 55,000tonnes/day openpit mine and plant produced a record 697,200 ounces of gold in 2018, with another 660,000 ounces expected in 2019 and 700,000 ounces in 2020 (350,000 ounces on 50% basis).

A stamp mill consists of a set of heavy steel (ironshod wood in some cases) stamps, loosely held vertically in a frame, in which the stamps can slide up and down. They are lifted by cams on a horizontal rotating the cam moves from under the stamp, the stamp falls onto the ore below, crushing the rock, and the lifting process is repeated at the next pass of the cam.

The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon. CIL stands for carboninleach. This is a gold extraction process called cyanidation where carbon is added to the leach tanks (or reaction vessel) so that leaching and adsorption take place in .

The plant is a conventional CIL (Carbon In Leach) plant with a capacity to process about 340,000 tonnes per year of Charters Towers gold bearing ore. There is also a substantial gravity gold recovery circuit planned to be installed within the overall plant design to recover the coarse gold particles.

This plant processes 4 million tons of ore per year with an average gold content of ounces of gold per ton of ore. Approximately 85% of the gold is recovered in the plant. From the ball and/or autogenous mill, slurry is pumped to the CIL leach tanks where lime adjusts the pH, if necessary, and it is agitated for the desired period of time.

New and Used Gold Recovery Trommels for Sale Savona Equipment is your source for New, Used, and Reconditioned Trommels for recovering gold and other precious metals from placer mining operations. We supply 18 inch, 30 inch, 48 inch, 60 inch, 7 foot Trommels for Placer Mining.

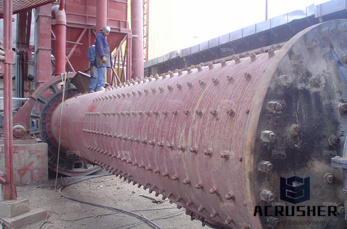

Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill. To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at to

The Plant Metallurgist reports directly to the Mill Superintendent, is responsible for the development of metallurgical processes or practices and operational control parameters required to attain optimum valuable metal concentration and recoveries from the ores. He is responsible for the efficient operations of the gold room.

Jan 04, 2018· Cyanidation machine supply please contact email: rocky

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE'' offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten and ...

Gold Stryker® GS7000LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation. The Gold Stryker® GS7000LDuses a large 25 HP Honda Industrial engine for many years of trouble free use.

GOLD PROCESSING PLANTS. Portable placer gold processing plants for alluvial mining, screen deck classifying jigs for alluvial dredging and mining, self contained gold processing plant, fine gold recovery, gold processing plants, gold processing plant, mine plant, mining plant, mining plants, placer gold recovery plant, gold processing plants, GOLD, PROCESSING, PLANTS.

WhatsApp)

WhatsApp)