Used Ballmills For Sale

Buy used Ballmills from King Industries. We can help guide you to the best solution for your equipment needs.

WhatsApp)

WhatsApp)

Buy used Ballmills from King Industries. We can help guide you to the best solution for your equipment needs.

Equipment Design Equation Ball Mill Customer Case

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the ...

Ball mills have been used for decades to grind and mix materials used in the ceramic industry. SHIMPO''s heavyduty ball milling machines enable very precise milling, in porcelain jars, even for relatively tough materials, wet or dry. SHIMPO ball mills have a compact design that is ideal for smallscale production and is constructed using

Ball Mill for Sale. APPROXIMATE CAPACITIES. All ball mills operate on the same principles. One of these principle is that the total weight of the charge in the millthe sum of the weight of the grinding media, the weight of the material to be ground, and any water in the mill—is a function of the percentage of the volume of the mill it occupies.

New and Used Ball Mills for Sale Savona Equipment is a new and used Ball Mill supplier ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

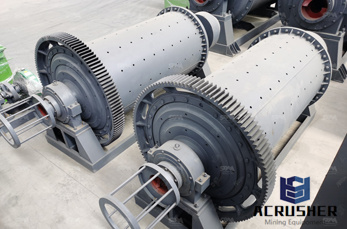

Ball mill, also known as ball grinding machine, a wellknown ore grinding machine, widely used in the mining, construction, aggregate start the ball mill business since 1985, supply globally service includes design, manufacturing, installation, and free operation training.

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

Slice Mills™ are identical to the Ball Mills and Ceramic Lined Mills in diameter and design The only difference is that they are as little as 12" in length. Since mill diameter dictates performance and mill length only affects capacity, Slice Mills™ are used to develop or .

Orbis Machinery, LLC is a process equipment design, engineering, and manufacturing company. We specialize in mixing, blending, plus ball mill and roll mill solutions for the processing industry. If you''re interested in improved productivity from your process equipment, call the pros at Orbis today.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

PATTERSON Industries Canada "The Process Equipment People" designs, engineers and manufactures Batch Continuous type Ball Pebble Mills mainly for the Coatings, Minerals and Metal Powder Industries together with the MilReactor® for specific Chemical Processing applications.. At PATTERSON we offer our many years of technical and engineering experience in analyzing your .

The Description and Function of Ball Mill: Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and nonferrous metals and glass ceramic industry.

With more than 100 years of experience in ball mill technology, ''s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

Metallurgical ContentOptimize Ball Mill Liner ReplacementLorain Shell LinersMill HEAD LINERSMill LINER BOLTSEffect of Liner Design on Mill Performance There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected ...

Equipment design equation ball mill suttonseedsindia ball mill designpower calculation the basic parameters used in ball mill design power calculations rod mill or any tumbling mill sizing are material to be ground characteristics bond work index bulk den,Equipment design equation ball mill.

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Equipment Design Equation Ball Mill, ball mill design equations and modelling pdf CS Cone Crusher Mobile Jaw Crusher MTW Milling Machine PEW Jaw Crusher PFW Ball mill Wikipedia The ball mill is a key piece of equipment Aside from common ball mills there is a second type of ball mill called a planetary ball mill.

In remote areas, grinding balls are usually received in welded 55 gallon drums each of which weighs between 500 and 600 kilograms. Suitable handling equipment for grinding media must be supplied by the design engineer. It should be noted that the ability to assemble a graded ball charge at the mill site prior to startup may not be possible.

General Information/Equipment Design Size reduction in impact crushers occurs through particle concussion by rigid forces. The hammer crusher, also called the hammer mill.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Jun 19, 2015· The only assumptions required for determination of the single ball trajectory are a coefficient of friction between the ball and mill lining, and unobstructed free fall .

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming ...

Xinhai mineral processing equipment mainly include: grinding equipment, flotation equipment, dewatering equipment, magnetic separation equipment, and so on. Some of the equipment is Xinhai independent research and development, and has been awarded national patent. ... Cylindrical energy saving grid ball mill design consist of feeding part ...

WhatsApp)

WhatsApp)