(PDF) Medium Density Control for Coal Washing Dense Medium ...

On one hand, the coal washing plant s tudied is operating 16 h per day with 15 DMC modules, the % energy reduc tion when β increases from 0 to translates to a daily energy

WhatsApp)

WhatsApp)

On one hand, the coal washing plant s tudied is operating 16 h per day with 15 DMC modules, the % energy reduc tion when β increases from 0 to translates to a daily energy

Coal Washing Plant has 1,063 members. Engineers and business opportunities discussion on coal washing technologycoal preparation technology....

Coal washing is a process that is undertaken in a coal washery or coal preparation plant (CPP) where coal is refined or cleaned of impurities. Coal washing involves using water, mechanical techniques and relies on gravity and the difference of density between coal and it''s impurities which are usually more densely packed due to the fact that ...

The Parnaby Dense Medium Cyclone Plant uses modern separation techniques for washing and separating materials including coal washing and coal preparation Toggle .

Apr 10, 2019· After washing, the coal can remove a lot of impurities and wash 100Mt of raw coal., can save 9600Mtkm capacity. LZZG washing solutions for Coal washing plant process. LZZG Coal washing plants are mainly used to remove impurities from raw coal or to classify high quality coal and low quality coal.

run at Satpura TPS a coal beneficiation plant at Piparwar mine of CCL was commissioned in 1997, which is supplying beneficiated noncoking coal to NTPC power station at Yamuna Nagar, Haryana and Dadri, UP. Another coal preparation plant for beneficiating noncoking coal at Bina, NCL, has also been commissioned. Installation of several more such ...

Oct 10, 2017· The new project specifically entails the construction of a 2 x 300 tph modules dense media separation (DMS) coal washing plant in Mpumalanga. The envisaged plant will wash discard dump coal at a rate of 3,96 Mtpa with the potential to increase to almost 8 Mtpa spanning its seven years of planned operation.

coal washing plants, coal washing plants Suppliers and For improving the quality of the sand, it can wash tiny stone power and impurity from the mixing san

Yield % Washing fee Rs/ton 130 Plant Benefits Added Plant and Micro Plant Added Washed AR Ash% Yield % 90 Washing fee Rs/ton 130 Washed AR Ash% Yi ld % 64 8 W hi f Comparative Costs of Supplying Washed Coal of Various Ash Contents at Quantities Required to Provide Equivalent Heat of Base Raw Coal to Varying Distances from the ...

Coal Wash Plant. Parnaby Cyclones provide a wide range of both mobile and modular wash plant for the coal preparation industry. Parnaby Cyclones is a long established family business, founded back in 1973 by Derek Parnaby who developed the world famous ''Parnaby Process'' for minerals separation using barrels and cyclones.

The plant has capacity to operate at million tonnes per year. The exposed coal is hauled from the mine to the heavy media wash plant where the waste is removed and then loaded on trains to be shipped to the ports.

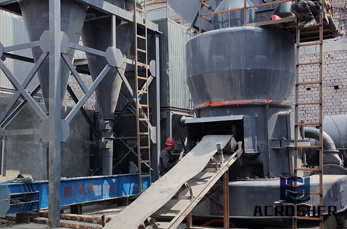

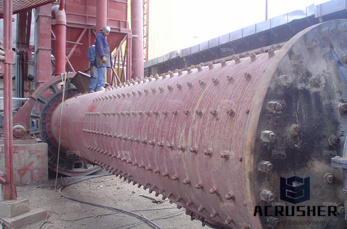

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

Mar 27, 2019· Taking a coal washing plant in Indonesia as an example, the coking coal preparation plant with an annual processing capacity of 4 million tons can increase the processing capacity per hour to more than 700 tons, and the power consumption, media consumption, fuel consumption, and water consumption are all reduced. At present, the whole plant ...

Sharghi coal washing plant, Northeast Iran (Figure 1) was evaluated by the slight modifications made on the Folchi algorithm previously modified by Mirmohammadi et al. (2009) and development of its impacting factors. Figure 1. Location of the study area (AlborzSharghi coal washing plant.

Coal washing Coal that comes from a mine is a complex mixture of materials with a large variety of physical properties. In addition to the coal itself, pieces of rock, sand, and various minerals are contained in the mixture. Thus, before coal can be sold to consumers, it must be cleaned. The cleaning process consists of a number of steps that results in a product that is specifically suited to ...

Coal Washing Plant / Coal Preparation Plant. HOT Mining is leading in the design, construction and operation of coal washing plants (coal handling and preparation plants, hereafter "CHPP").. The Joint Venture of HOT – SCCDRI has delivered over 20 CHPPs with capacity from 90 TPH to 3125 TPH.

New RD Olson portable wash plant with 5'' wide x 16'' long triple deck incline wet screen, 20 electric motor drive, 100 mm bearings with oil bath lubrication, manifold for water supply with 5 spray bar wash .

The coal wash plant was completed in February 1971. The first coal ship was loaded in October of 1971sert_galleryConclusion. Fluor provided design and construction services on the Goonyellay Point coal processing facility and port. This project was the second major coal project completed by Fluor in Queensland, Australia.

Our Coal wash plants use highly scaleable robust process technologies. 1. Dense medium cyclone and spiral circuits are standard technologies for washing. Consulmet can combine these with floatation circuits to provide a complete coal handling and preparation solution.

How Much Does It Cost To Build A Coal Washing Plant? It is easy to ask the question "how much does it cost to build a coal washing plant", but hard to find the right answers. Since there is a standard response to all! This issue not only makes the company''s engineering and Design Institute to go crazy, but it is also a great challenge for many ...

Modular Wash Plants, such as the McLanan UltraWASH, are assembled from containerized washing modules and produce up to five products, including three clean aggregate and two washed sand fractions. Additional modules can be added as needed to create a complete wet processing plant that is flexible enough to meet any production need.

The scheme used in physical coal cleaning processes varies among coal cleaning plants but can generally be divided into four basic phases: initial preparation, fine coal processing, coarse coal processing, and final preparation. A process flow diagram for a typical coal cleaning plant .

Coal Washing Problems associated with Indian runofmine coal ¾Indian coal has drift origin, resulted in intimate mixing of mineral matter with coal, giving rise to the ash content ¾The coalash distribution in the coal matrix in Indian coal is so interwoven that coal is essentially required to

Sep 06, 2019· Coal ash, a catchall term for several kinds of waste left over at power plants that burn coal, typically contains a number of substances harmful .

WhatsApp)

WhatsApp)