coal mill in power plant en

Coal Mill Of A Thermal Power Plant Stock Photography Image ... Coal Mill Of A Thermal Power Plant Download From Over 61 Million High Quality Stock Photos, Images, Vectors. Sign up for FREE today. Image: . Get Price

WhatsApp)

WhatsApp)

Coal Mill Of A Thermal Power Plant Stock Photography Image ... Coal Mill Of A Thermal Power Plant Download From Over 61 Million High Quality Stock Photos, Images, Vectors. Sign up for FREE today. Image: . Get Price

Jan 16, 2018· Shuttered coal plant fixeruppers for sale all over the ... ENGIE North America''s MW Mount Tom Solar Project was built at the site of the shuttered Mount Tom Power Station coal plant ...

Dec 13, 2011· A vertical spindle mill is also designed for pressurized and suction type requirements. Boiler designers use this type of mill for poor quality coal as this type of mill rejects foreign materials like stones and other high density materials. The power consumed by the mill per ton of coal ground is only twothirds of the ball mills.

micro mill sieg x0 update, sieg sx2 mini mil. Thousands of PF Series Impact Crushers are installed all over the world . Mill Super X3 Mill LAST UPDATE 4/5/10 . coal based thermal power plant .

LOESCHE coal mills are costeffective, proven product based on robust engineering concepts. With a low power consumption, low noise and high efficiency operation, the large range of 2, 3 and 4 roller models mean there is a LOESCHE coal mill to suit any application.

For nearly 100 years—ever since pulverized coal combustion was adapted for power generation—GE has been a leader in coal mill technology for the power industry. That leadership continues today with the world''s largest fleet of installed power milling equipment.

There are many types of mills and bowl mill is one of them, all these mills can face coal hangup. For taking corrective action during a coal hangup in bowl mills the operator will have to know the reason for such a hangup, how the plant will respond, what he has to respond to and what the local operator will have to do. This will reduce the chance of mill trip and bring back boiler to ...

The mill model is running in parallel with the power plant coal mill operation; the measured and predicted outputs are displayed on the computer screens in the power plant control room. When the measured and predicted mill outputs are over the preset threshold values, the system will raise alarm reports to give warning signals.

Coal 588 NRG Energy: 1959 Herbert A. Wagner Generating Station: Anne Arundel County, Maryland: Coal 495 Talen Energy: 1956 2020(136MW) Luke Mill Power Plant Luke, Maryland: Coal 65 Verso Corporation: 1958 Morgantown Generating Station: Newburg, Maryland: Coal 1,252 NRG Energy: 1970 Warrior Run Generating Station: Cumberland, Maryland ...

m oisture in the raw coal, preventing the m ea surem ent from being u sed in con trol. In this paper,w e propo se a n on line c oal m oisture e stim ator to b e used by po w er plant op erating p ersonn el, so that they m ay take the m oisture into con sideration w hen p lann ing the plant op eration . T he propo sed estim ator uses alrea dy ...

Click on the locations shown on the map for plant details. (To return to the map of existing coal plants in the, click here.) For additional information on coal issues in North Carolina, click here. For a list of proposed new coal plants in North Carolina, click here.

{{#badges: CoalSwarm| Climate change}} Muskogee Mill Power Plant is a coalfired power station owned and operated by GeorgiaPacific Corporation which, in turn, is owned by Koch Industries in Muskogee, Okloma. The plant provides power to GeorgiaPacific''s Muskogee paper mill.

Beater wheel mills are designed to prepare a coal powder airfuel mixture for combustion in furnace chambers of coalfreed power plants by coal drying, pulverizing, classifying and transport. Their multipurpose function usually results in operation instability accompanied by unacceptable vibration.

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in .

Thermal power plants use different types of coal pulverizers. The method used is attrition, impact, or a combination of both. This article explains the characteristics of the three main types attrition, impact and attrition, and impact or hammer. Selection of the type of pulverizer depends on the grindability of the coal, the capital costs and maintenance costs, and considerations for licensing.

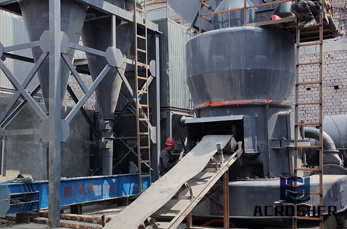

Coal Mill Design,Used Coal Mill in Power Plant for Sale in ... SBM is major coal mill manufacturer who can supply high quality equipment and design excellent solution for client with its 30 years experience in crushing and mill ...

Ball Mill Popular Coal Mill in Powder Plant. Because coal is the main purpose of fuel for power plants, and so will usually choose Ball Mill as a coal Mill in powder plant, Ball Mill, Ball Mill, the performance characteristics of Ball Mill for the edge of the transmission, by the motor through reducer, and the size of the gear drives the Mill ...

Coal Mill In Power Plant With Images – Gold Ore Crusher. Coal Mill In Power Plant With Images. The is the professional Gold Mining Equipments manufacturer in the world, located in China,India, along with other Asian .

Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion. In Part I of ...

Mar 29, 2017· The basic function of a pulveriser in a Thermal Power plant is to break down and crush the coal lumps into fine particle form before it is taken to the boiler for burning. Pulverisation of coal basically breaks the big coal lumps and increases the...

In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverizes the coal to particles.

Jan 09, 2016· Pulverizer or inother name Mill used for pulverized coal boiler of thermal power plant. The device pulverize coal to powder (pulverized coal) before blowing to burners of furnace.

Southwestern Corporation designs and manufactures coal mill / pulverizer products for CE, Babcock Wilcox, Foster Wheeler, and Loesche pulverizers. cable sweep ...

RingRoll (BowlMill) and BallRace Mills comprise the majority of coal pulverizers currently in service at power generating facilities. In this design the grinding rolls are stationary, while the ring (or bowl, as it is sometimes called) is rotated by a worm gear drive. ... the power plant installed one assembly on each of the 30 pulverizers ...

WhatsApp)

WhatsApp)