clinker grinding unit in china sale cement clinker ...

Jun 03, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

Jun 03, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

May 09, 2019· clinker size for cement mill ≤25 Introduction of clinker size for cement mill: Cement can be not only hardened in the air, but also better hardened in the water in which it will maintain and develop strength. So cement is kind of cementitious mate...

Clinker grinding aids. Gypsum is added to clinker primarily as an additive preventing the flash settings of the cement, but it is also very effective to facilitate the grinding of clinker by preventing agglomeration and coating of the powder at the surface of balls and mill wall.

Cost Of Cement Clinker Grinding Plant What should be paid attention to in the initial stage of Cement Clinker Grinding Machine? Cement Clinker Grinding Machines have been widely used in mineral processing, chemical and building materials industries.

Cement Clinker Grinding Plant price. Many people have a certain understanding of the Cement Clinker Grinding Plant. They all know that the equipment is a kind of equipment for fine powder production of various ores, industrial materials, construction materials, limestone, etc., and the models of the equipment are many and different.

serious challenge to obtain a good performance of a vertical roller mill in cement grinding. Today, however, the OK mill has become an excellent example of a mill design that has overcome the difficult grinding conditions associated with finish grinding of cement clinker and related products.

Cement Plant Machinery Walchandnagar . Vertical Roller Mill. WIL have successfully engineered, supplied and commissioned Vertical Roller Mills for raw material, coal/petcoke, slag and clinker grinding ...

The main models are LM series Cement Clinker Grinding Machine, LUM Cement Clinker Grinding Machine, MTM medium speed trapezoid mill, MTW European version mill. With its unique structural design and advanced grinding principle, the Cement Clinker Grinding Machine has become a technical performance that cannot be achieved by other equipment.

In some ore processing and production processes, Cement Clinker Grinding Mills are the main milling equipment. This type of Cement Clinker Grinding Mill is milled to a product size ranging from 325 mesh to 1800 mesh. The customer can adjust the particle size of .

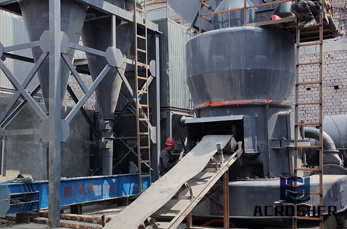

Grinding Technology Of The Cement Grinding Plant. The cement grinding plant is generally built close to the cement revenue market so as to lower the transportation cost. The cement grinding station produces the completed cement solutions by grinding the mixture of cement clinker, gypsum, cinder, and coal ash by using a right proportion.

The use of a good Cement clinker grinding aid can be vital in today''s increasing material demands. Along with the obligation to process increasingly larger quantities of ores containing finely disseminated minerals, our limited energy resources and the rising costs of energy present a challenge to the process engineer. One research route that has been explored for about half a century is the ...

Vertical roller mill is a kind of equipment used for raw cement, cement clinker, slag and clinker grinding processing, has the characteristics of simple structure, low cost of manufacture and use.

cement clinker mill cost and price | cement clinker grinding mill. Zenith''s ball grinding mills for cement clinker have a good reputation among our honored customers both at home and abroad. Besides, the cost and price of cement clinker ball mill is very reasonable and attractive for cement producers. Read more

Crusher operation raw mill operation rotary kiln operation cement mill operation vertical cement mill clinker quality cement quality white clinker Cement Grinding Aid Clinker and Cement Clinker and Cement Everyting for clinker and cement (in order to see the files please register)

Traditional clinker grinding station adopts ball mill to grind clinker, and has much dust, loud noise and high energy consumption in the process of production, it will be replaced gradually by vertical roller mill. Great Wall Machinery is the professional manufacturer of cement equipment, can offer complete solution for grinding station, and improves production efficiency, reduces power ...

Proven commercially, the OK™ mill is the premier roller mill for finish grinding of Portland cement, slag and blended cements. The mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is

offers 494 professional clinker mill products. About 13% of these are cement making machinery. A wide variety of professional clinker mill options are available to you, such as free samples.

As a popular kind of grinder, raymond mill is designed to process at least 200 kinds of minerals such as cement clinker, stone flour, barite, bentonite, calcium carbonate, clinker, coal, dolomite, lead xide, limestone, marble, quartz, ultrafine to name but a few.

It has been verified by practice that the calcite with a feed size of 25mm is used for grinding. When the fineness is adjusted to 1250 mesh (10um), the output can reach 400kg/h, and the input power is only 23kw. Significantly higher cost performance than traditional Clinker Grinding Mills.

project cost for cement grinding unit miningbmw project cost for cement grinding unit, Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, . know more Get Price And Support Online

what does a clinker grinding mill do. Our Purpose And Belief. LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service, striving to maximize and optimize the interests and values of the customers, and build bright future with high quality. All;

Metallurgical ContentRAW CEMENT GRINDINGWET VS DRY Grinding of CementCLINKER GRINDINGCement Grinding MillsHigh Efficiency Cement Grinding Mill The principle of Grate Discharge grinding is nearly universally adapted in the cement grinding industry. Grate Discharge Ball Mills are the rule rather than the exception. Rod Mills for raw and finish grinding begin to enter the picture. .

cement clinker grinding plant cost XSM is a leading global manufacturer of crushing and milling equipment (cement clinker grinding plant cost),XSM also supply individual (cement clinker grinding plant cost...) crushers and mills as well as spare parts of them.

WhatsApp)

WhatsApp)