1200tpd Gold CIP Plant in Tanzania YouTube

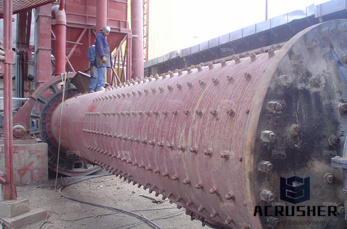

Sep 20, 2017· 1200tpd gold CIP plant in Tanzania ( a EPC project of Xinhai, adopting allslime cyanidation process with crusher, ball mill ...

WhatsApp)

WhatsApp)

Sep 20, 2017· 1200tpd gold CIP plant in Tanzania ( a EPC project of Xinhai, adopting allslime cyanidation process with crusher, ball mill ...

offers 142 gold cip production line products. There are 142 gold cip production line suppliers, mainly located in Asia. The top supplying country or region is China, which supply of gold cip production line respectively. Gold cip production line products are most popular in Domestic Market, Africa, and Eastern Europe.

drawing, cip gold plant BINQ Mining. Apr 09, 2013· The process design of gold leaching and carboninpulp . – saimm. The CIP process. A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2.

Jun 11, 2019· Scattered mining comprising a single shaft system is used at Kopanang. Shaft sinking was commenced in 1977 while production was started in 1984. Gold is processed using both conventional semiautogenous grinding and carboninpulp (CIP) technology, which produces uranium oxide as a byproduct.

Shandong Xinhai Mining Technology Equipment Inc. Exporter and Manufacturer of Gold CIP Production Line in Fushan hightech industrial development district, Yantai, Shandong, China. Get deals on Gold CIP Production Line at Tradeindia.

The Journal of The South African Institute of Mining and Metallurgy MAY/JUNE 2002 181 ... AAC PumpCell technology to high grade gold circuits is recent and the evaluation of these plants is covered in this paper. Anglogold ... comparison between PumpCell and CIP technology in terms of performance and cost was undertaken. This study was ...

Improve the bottom line of your mining operation with our cyanide expertise and carbon and resin gold recovery technologies. ... and SGS continues to remain at the forefront of this very successful gold recovery technology. ... This is a much less abrasive system meaning that the carbon lasts much longer than in a CIP process. ...

cip gold plant designs in south africa cip technology for gold mining solution for mining quarry . cip gold plant designs in south africa. cil gold processing plant, cil gold plant design technology, cip. Get Price. gold cil/cip plant public group facebook.

Gold CIP Production Line. Process Introduction. CIP (Carbon in pulp) process is a high efficient method to leaching and recovering gold from gold ore, The most different from CIL process is in CIP process, gold leaching and adsorption are separated, first leaching, and then adsorption.

Jan 04, 2017· Carboninpulp (CIP) is the sequential leach then absorption of gold from ore. During the CIP stage, pulp flows through several agitated tanks where sodium cyanide and oxygen have been added to ...

Ore mined is treated and smelted at Mponeng''s gold plant. The ore is initially ground down by means of semiautogenous milling after which a conventional gold leach process incorporating liquid oxygen injection is applied. The gold is then extracted by means of carboninpulp (CIP) technology.

cip gold processing plant for sale suttonseedsindia. gold,nickel and copper mining and. ores include bauxite,copper,gold,iron,lead and in metal mining and processing are exposed,not only to the metal of interest,but also to various. cip gold processing plant hot sale in saudi arabia. best ability small scale gold mining machine for ...

Gold CIP Production Line Shandong Xinhai Mining Technology . Gold CIP Production Line adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching is very useful ...

Gold CIP process adsorbs gold from cyaniding pulp by active carbon including 7 steps: leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit, carbon acid regeneration, leaching pulp. Gold CIP system is a useful gold recovery method in mineral processing.

Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%.

Improve the bottom line of your mining operation with our cyanide expertise and carbon and resin gold recovery technologies. ... and SGS continues to remain at the forefront of this very successful gold recovery technology. ... This is a much less abrasive system meaning that the carbon lasts much longer than in a CIP process. ...

Gold Mining Equipment List. Making a complete list of gold mining equipment starts with defining the type of gold mining you are doing and the budget you have at your disposal. The type of mining relates to hard rock, eluvial, or placer; alluvial deposits. The capital budget you have to invest in buying your equipment with dictate the scale at ...

Major advances in the practical application of CIP technology have been made over the last few decades resulting in this technology being firmly entrenched in the gold mining sector. However, CIP dynamics are not always well understood by plant operators and engineers.

CIL stands for carboninleach. This is a gold extraction process called cyanidation where carbon is added to the leach tanks (or reaction vessel) so that leaching and adsorption take place in the same tanks. CIL is slightly different from another gold extraction process called CIP or carboninpulp process.

Extaccion process cip gold flotation equipment gold goldold cip related equipment for chrome ore in south africaold cip related equipment for antimony ore in albania gold mining accumulator conveyor china gold supplier high grade solid plate belt fastener floatation process gold plants in turkey what is the method of gold extaccion cip gold ...

The Production Line of All Sliming Cyanidation CIP Process. All sliming cyanidation CIP method to gold smelting process refers to all the gold ore grinding pulverized pulp (200 mesh content of 90 ~ 95%), the first cyanide leaching, and then use activated carbon absorb charcoal gold .

HOT is committed to helping clients to recovery gold in CIL process more environmentally and efficiently,and spreading the advanced and mature mineral processing technology and equipment.

With the rising gold prices in recent years, it further stimulated the rapid development of gold industry. As the exhaustion of highgrade gold ore, researching on middlelow grade and refractory gold ore and strengthen the traditional gold mining process undoubtedly have become the main trend in global gold beneficiation industry.

Gold Mining Process Development . THE BASIC PROCESSES OF GOLD RECOVERY ... (CIP): Carboninpulp operation is a variation of the conventional cyanidation process. Ore is crushed, finely ground, and cyanide ... commercially viable gold and silver recovery mining processes. We can suggest the optimal process and equipment for virtually any ore ...

WhatsApp)

WhatsApp)