Cement Mill Dal Teknik

The shell lining in the second compartment or in one compartment finishgrinding mill has special classifiying plate lining and a charge of smaller balls for fine .

WhatsApp)

WhatsApp)

The shell lining in the second compartment or in one compartment finishgrinding mill has special classifiying plate lining and a charge of smaller balls for fine .

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

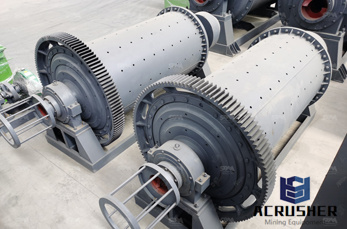

Feb 22, 2019· Cement Ball Mills. A cement ball mill is designed to grind clinker, gypsum and for the drying of cement additives. It is a component in the cement making process. Today''s Ball Mills are typically designed with a slide shoe bearing. These bearings have replaced the more traditional trunnion bearings, as they are less expensive to purchase and ...

cement mill trunnion bearing cooling . Ball Mill Trunnion Cement Mining Great Wall Steel . Ball mill trunnion is an important part to load the mill rotary body. The neck that connected to bearing liner and the circular that connected to mill . Contact Supplier

cement mill trunnion bearing parts supremewheelscoza. Replacement Of Cement Mill Trunion Bearings what are appliion Trunnion Bearing in Ball MillFAQs ball mill,cement provided by the hydrostatic trunnion bearings Ball Mill, Rod Mill, SAG Mill, provides grinding mill parts for equipment previously sold under a variety of mill parts, such as ...

Cement Mill, Main Gearbox, Gear Oil, Portlandzementwerk Wittekind Hugo Miebach Söhne, ASIN5156 Cement Mill, Trunnion Bearings, Fixed Floating, Lube Oil, Cement Plant in Ireland, ASIN5159 Cement Mill_Oven Gear FLS TD1500_Gear Oil_Aalborg Portland_ASIN5002 Cement Mill_Rotary Kiln Trunion Bearing_Lube Oil_Golden Bay Cement_ASIN5118

Trunnion Mill Bearing Fluid Improve HighTemperature Trunnion and Mill Bearing Overloading. We solve trunnion and mill bearing lube problems for people in the chemical, waste, food processing, lime, cement and paper industries. We provide expert consulting and field troubleshooting support to help our customers find the best lubricating products.

Anion Specialty Chemicals is a leading supplier of specialty lubricants and chemicals to the pulp and paper, cement, and mineral processing industries. We are an industry leader for melting lubricant bars, kiln trunnion, dryer and mill lubricants, graphite blocks, resurfacing solutions for mechanical applications, and related field services.

Oilcooling by water circuit inside the trunnionbearings. Torsionshaftbearings: 3 Torsionshaft bearings with white metal splitbushes (200 mm Ø x 350 mm width) Possible reconstructions: Conversion to a one or twocompartment opencircuitmill. Shortening of milltube to abt. m length. Get more informations: info

The spherical roller bearings used in FSDR .. K housings can be relubricated via two drilled and tapped G 3/8 holes in the housing base ( fig. 1 ). SKF recommends using an automatic lubrication system like the SKF MultiLube pumping unit .

Aug 07, 2018· CHAENG is specialized in manufacturing large steel casting parts for ball mill: ball mill trunnion, ball mill main bearing, ball mill bearing pedestal, ball mill girth gears and so on ...

May 12, 2013· Increase in cement mill trunnion bearing temperature. What are the causes for an increase of Cement Mill trunnion Bearing temperature and what are the possible solutions. Reply. Know the answer to this question? Join the community and .

Metallurgical ContentBall Mill TRUNNION BEARINGSTrunnion BRONZE BUSHINGSTRUNNION BASE AND CAPBall Mill LUBRICANT JACKSBall Mill PINION SHAFT BEARINGS The first part of the mill that we will look at is the TRUNNION BEARING. This is a HYDROSTATIC BEARING which is a slow moving bearing that carries a heavy load. Usually it is constructed from Babbitt''s metal.

Trunnion bearing and Slide Shoe bearing are two main classifications of Ball Mill bearing, and while making a choice between these two, you should refer to these following points: 1. If a person is looking for a higher load machine where the surface area is restricted, Trunnion Bearings works the best.

HDU 27/ series . HDU 27/ is a fine filter for offline oil filtration for medium to large hydraulic power transmissions, lubrication, cooling and quenching systems. ... Cement Mill, Trunnion Bearings, Fixed Floating, Lube Oil, Cement Plant in Ireland, ASIN5159

• Pinion Gear for Cement Kiln • Kiln Gear Reducer • Kiln Carrying Roller • Kiln Carrying Roller Bearing Bushing • Clinker Cooler Grate Plate • Motor for Ball Mill • Cyclo Gear Reducer • Ball Mill Trunnion Head • Main Bealing for Ball Mill • Shell Liner for Ball Mill • Diaphragm for Ball Mill • Crusher • Filter Bag for ...

trunnion bearing on cement mills . cement mill trunnion bearing lubrication methods cement mill inlet trunnion bearing lubrication methods BINQ provides both small ball mill and big ball mill; Chat Welcome to EDGC Founded in 1987, EDGC has attained 124 patents during the production of crushers mills over the past 30 years 22 overseas offices not only .

Jan 13, 2014· Mill Lubrication System 1. OBJECTIVES: To identify the definition and importance of a hydraulic lubrication system. To be familiarized with the lubricant and equipment used in the system. To understand the process and various design of Mill lubrication system. To identify some problems encountered by the system, and formulate some recommendation to help fix the problems.

On a 11''6" x 22''0" Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill. System monitors including pressure switches and flow monitors are provided, along with temperature sensors that monitor ...

The shell lining in the second compartment or in one compartment finishgrinding mill has special classifiying plate lining and a charge of smaller balls for fine .

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Kolkata Cement Mill Trunnion Bearing Cooling. Kolkata Cement Mill Trunnion Bearing Cooling. We are a largescale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment. Get Details

Cement mills Extremely high viscosity bearing grease with solid lubricants SKF LGEV 2 is a premium quality, extremely high viscosity, mineral oilbased grease using a lithiumcalcium soap containing molybdenum disulphide and graphite.

Ball Mill. We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications. Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on the basis of the product fineness, quality, and nature of raw material, site conditions and specific requirements.

WhatsApp)

WhatsApp)